Power Plants

Powering the Future, Every Step

The Edeltech Group successfully operates five privately owned power plants: Dorad, Ramat Negev , Ashdod Energy Orot Yosef and Orot Pnina, and it will soon begin operating an advanced solar plant.

Sorek Power Plant is expected to begin operation by 2029.

Dorad Energy

Location: South of Ashkelon

Operational technology: Combined cycle, fired by natural gas as the primary fuel source and diesel as backup

Year operations began: 2014

Output: 860 MW

Operations and maintenance company: Edeltech O&M, a member of Edeltech Group

It is interesting to note: The Dorad power plant is built differently from most of the power plants in Israel and includes two groups of six General Electric gas jet turbines. This configuration enables greater operational flexibility than the standard production units, by adjusting production ability to varying demand, and offering higher resilience in the face of malfunctions.

Ashdod Energy

Location: Adjacent to the Adama Agan plant in Ashdod’s northern industrial zone.

Operational technology Combined: cycle that enables generation of electricity and steam with high utilization

Year operations began: December 2015

Output: Approximately 55 MW

Operation and maintenance company: Edeltech O&M, a member of Edeltech Group

It is interesting to note: In addition to regular supply of electricity to the Adama Agan factory, the plant also supplies approximately 40 tons of steam/hour, produced through a gas turbine, steam generators and a steam turbine. The plant supplies electricity to various other electricity consumers through the national electric grid. Surplus electricity is sold to the Israel Electric Corporation

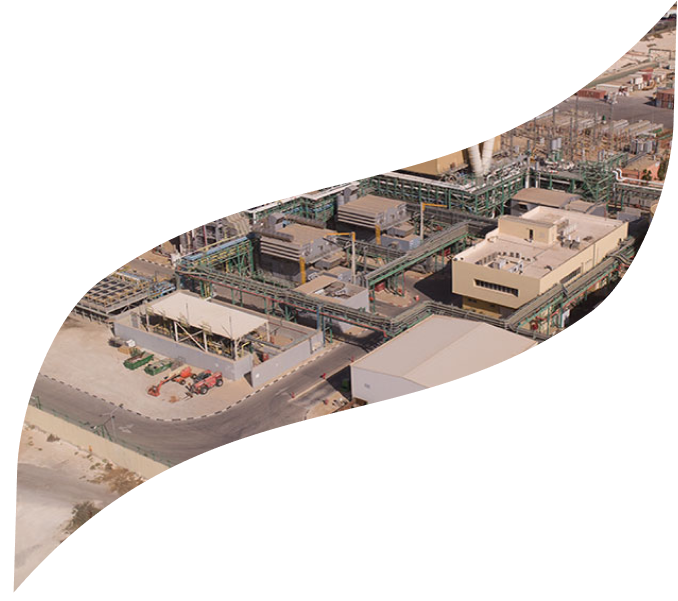

Ramat Negev Energy

Location: Adama Makhteshim plant, in the Neot Hovav Industrial Zone

Operational technology: Natural gas as the primary fuel source and diesel as backup

Year operations began: January 2016

Output: Approximately 120 MW in combined cycle

Operation and maintenance company: Edeltech O&M, a member of Edeltech Group

It is interesting to note: The power plant actually implements an advanced environmental philosophy that seeks to achieve numerous benefits from a single production process. Additional outputs from the plant’s activity are close to 300 m3 of desalinated water per hour and compressed air that are used by the industrial customers in the region.I

Orot Yosef

Location: Ramat Hovav, South Israel

Operational technology: Open Cycle & Combine Cycle

Year operations began: 1989

Output: 1195 MW

Operation and maintenance company: Ramat Hovav Power Plant Operation and Maintenance Limited Partnership, a member of Edeltech Group

It is interesting to note: The power plant consists of 9 units on 126 duams. The station is situated in a central infrastructure junction, and enjoys two electrical connections to both the high voltage (161 KV) and the super high voltage networks, as well as a connection to the national natural gas pipeline and a diesel pipeline.

Orot Pnina

Location: Ein Tut junction, Israel

Operational technology: Combine Cycle

Year operation began: 1994-2002 as Combine Cycle Facility

Output: 676 MW

Operation and maintenance company: Hagit East Power Plant Operation & Maintenance Limited Partnership

It is interesting to note: The power plant consists of 6 turbines, which are arranged as 2 Combine Cycle plants. The station is situated in a central infrastructure junction, and enjoys two electrical connections to both high voltage (161 KV) and the super high voltage (400 KV), as well as a connection to the national natural gas and liquid fuel pipelines.

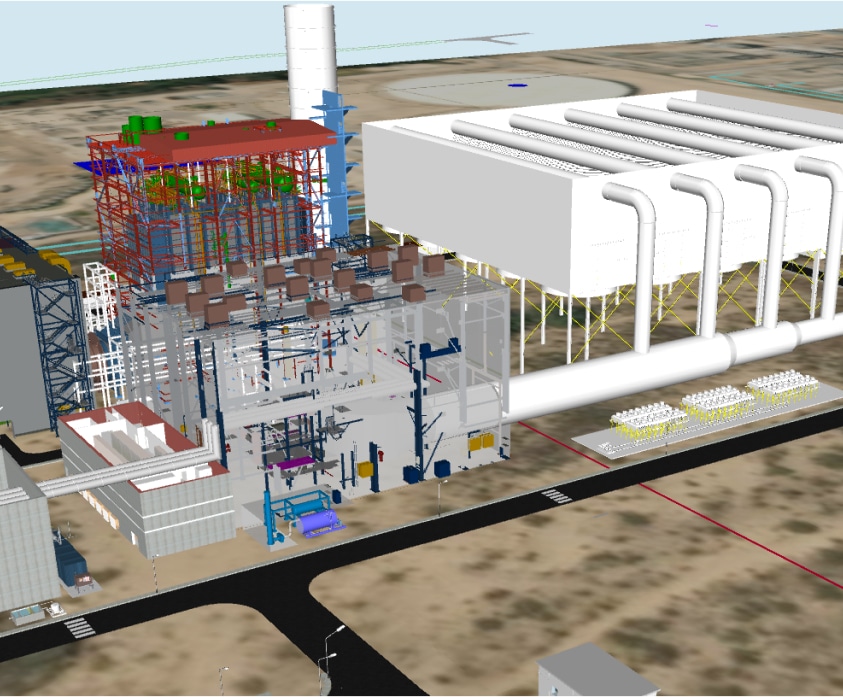

Sorek Power Plant

Location: Sorek, Central Isreal

Operational technology: Combined Cycle

Year operations will begin: 2029

Output: 630MW to 900MW with an option to extend the Installed Capacity in the future up to 1,400MW

Operation and maintenance company: Sorek Power Plant Operation and Maintenance Limited Partnership (In Formation), a member of Edeltech Group.

It is interesting to note: The power plant shall be based on the use of one CCGT unit comprising one combustion turbine and one condensing steam turbine with generator in a single-shaft or multi-shaft configuration. The power plant shall be equipped with essential ancillary equipment, one heat recovering steam generator, one heat rejection system, balance of plant equipment and facilities required for maintained operation of the Plant. The combustion turbine shall be capable of running on natural gas and diesel fuel, for which the latter is back-up fuel for the combustion turbine.